PRODUCTS

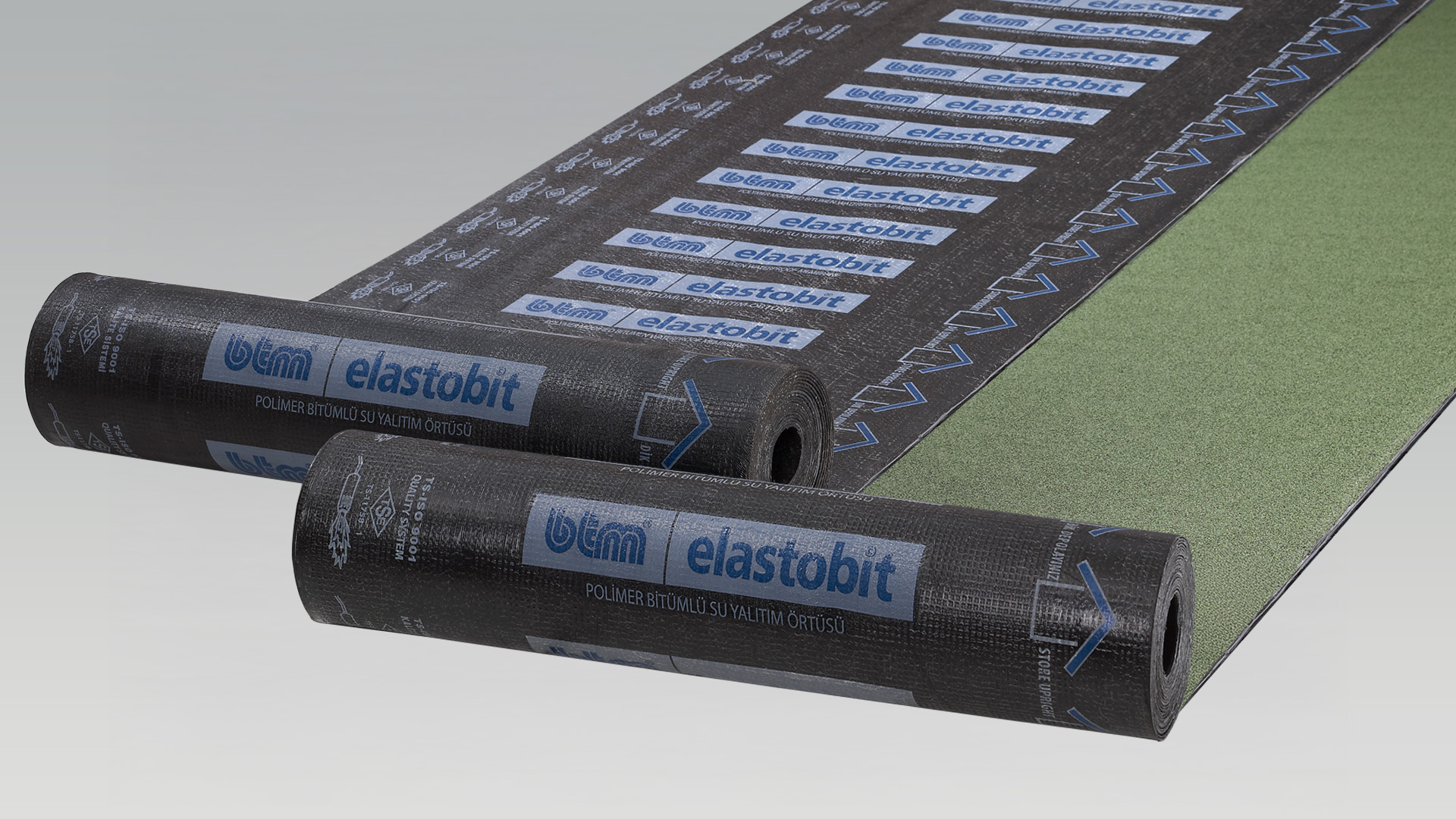

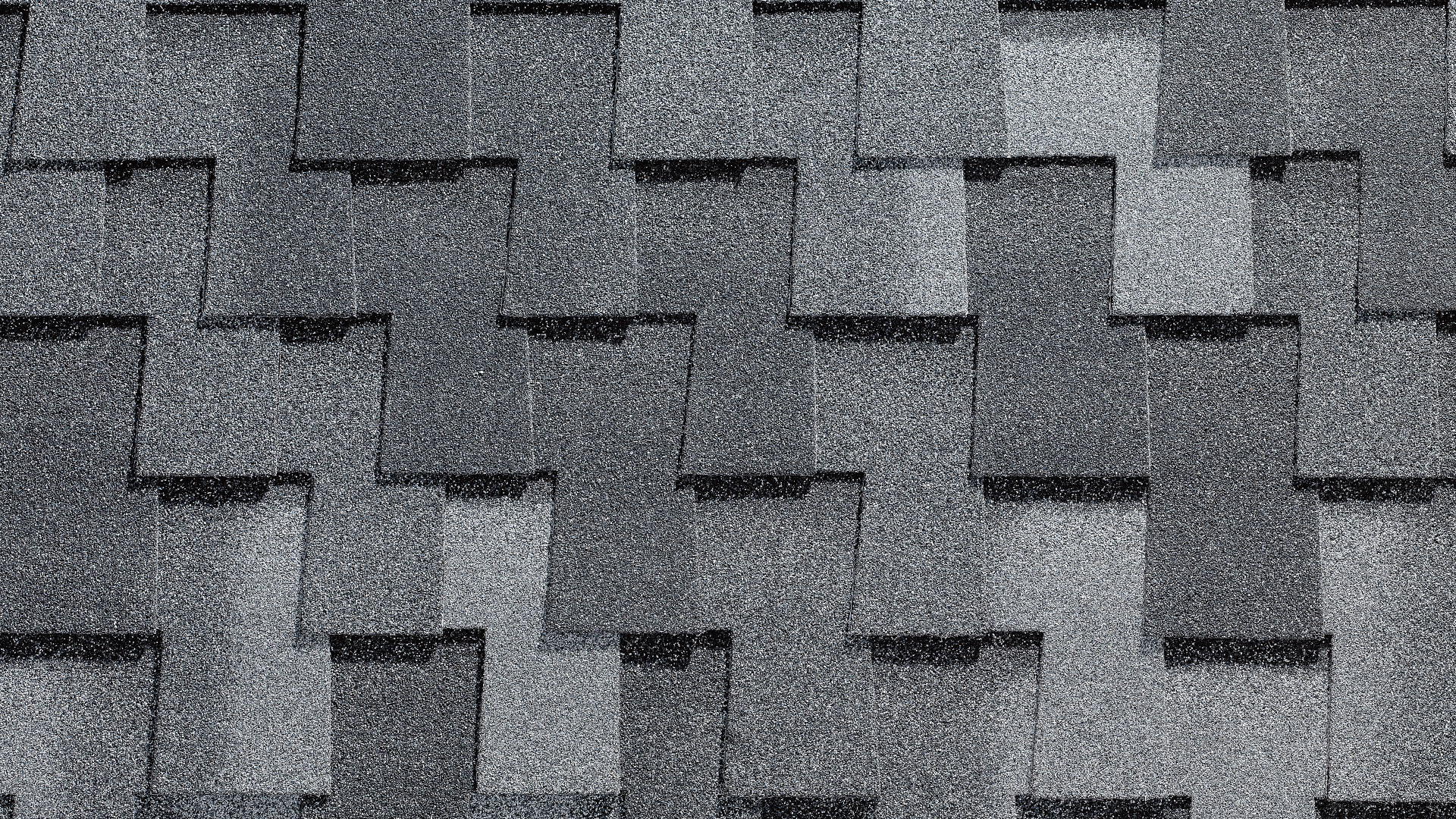

BTM Elastobit

ADVANTAGES

It has the superior flexibility and cold performance of bitumen with SBS. It can be bonded with torch or hot asphalt.

PLACES OF USE

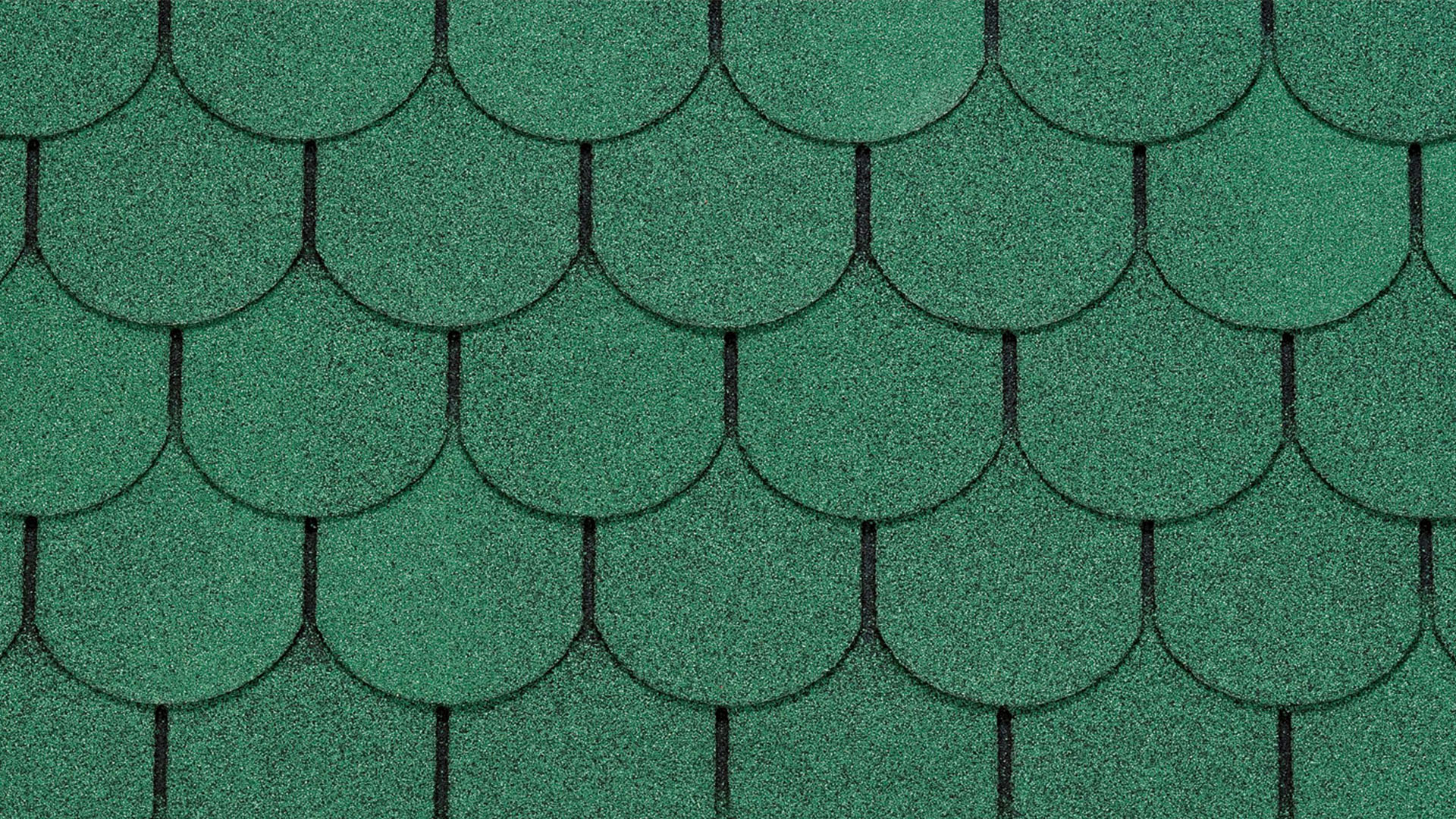

Used to obtain water and moisture impermeability on:

- terrace roofs of buildings,

- sloping concrete roofs,

- curtain walls, foundations.

- May be used as bottom layer insulation membrane on light metallic and prefabricated roofs.

- It is not only designed for cold climates but may also be used as lower and middle layer membrane in waterproofing to be made on any surfaces which contact any types of soil and require elasticity.

- It is used in the insulation of pressurized and non-pressurized underground or surface waters.

SURFACE PREPARATION

Surface on which application shall be carried out must be cleaned of any dust, dirt, rust and grease and any loose parts scraped.

APPLICATION

If the surface to be insulated is concrete, then it must have been finished with sloping grout burnished using a wooden trowel and be clean and dry. Before the application of the membrane, the surface must have been spread with bituminous solution undercoat BITUSOL (TS 103) or bituminous emulsion undercoat BITUMER (TS 113) and allowed to dry up. Depending on the slope of the ground, BTM Waterproofing Membrane Elastobit application starts from low to high elevations. BTM Elastobit is adhered to the surface by heating it with a torch flame. There must be staggering between rows. A 15 cm overlap should be left for the short side overlaps of 1 meter, and at least 10 cm should be left for the long side overlaps, and a roller should be used for adhering the joints. Between the layers, there should be a 50 cm staggering on the short side and 5 m on the long side.

PACKAGING

Elastobit is launched into the market in rolls 1m wide and 10m long.

STORAGE CONDITION AND SHELFLIFE

The membrane rolls should be stored vertically under a roof, protected from direct sunlight. If the rolls have to be stored outdoors for a long period of time, they must be covered with a protective layer in order to protect them from the sunlight. The membrane rolls or pallets should not be stacked on each other.

![]() BTM Bitümlü Tecrit Maddeleri Sanayi ve Ticaret A.Ş. Kemalpaşa O.S.B. Mahallesi Gazi Bulvarı No:152 35730 Kemalpaşa/İzmir TURKEY Phone:+90 232 877 04 02 Fax:+90 232 877 04 10 info@btm.co • www.btm.co

BTM Bitümlü Tecrit Maddeleri Sanayi ve Ticaret A.Ş. Kemalpaşa O.S.B. Mahallesi Gazi Bulvarı No:152 35730 Kemalpaşa/İzmir TURKEY Phone:+90 232 877 04 02 Fax:+90 232 877 04 10 info@btm.co • www.btm.co